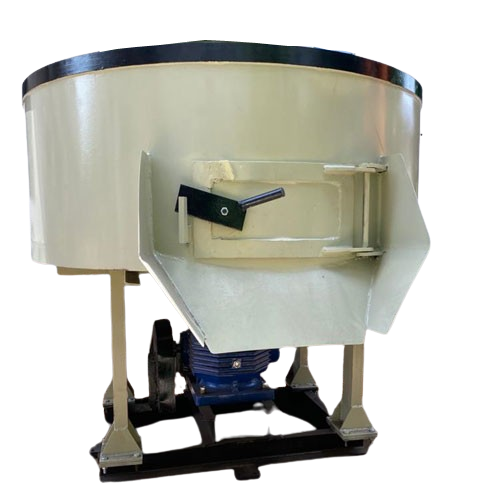

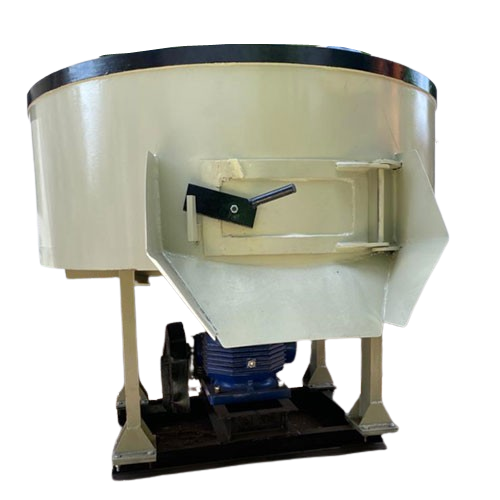

C.R.Overseas is the Effective Sand Muller manufacturers in Bharuch. The Sand Muller that we manufacture is engineered to efficiently mix sand with binders and additives, ensuring that you get a more consistent and homogenous mixture. This is crucial for construction projects where the quality of the sand mixture directly impacts the strength and durability of the final product. We are well aware of the issues that arise at the customer's end for mixing the sand evenly with all the additives that are necessary for construction. The semi-automatic operation features that you get with our maed Sand Muller help in combining the benefits of automation with the flexibility of manual control.

We are the most Proven Sand Muller suppliers in Gujarat. This allows the operators at your construction site to easily adjust mixing parameters based on the specific requirements of each batch, ensuring optimal results every time. When you automate the mixing process to a certain extent that is boring and laborious the manual way, our Sand Muller helps you save time and labour on construction projects. This allows workers to focus on other tasks, increasing overall productivity and efficiency on the job site.

Consider us for all the needs of your Sand Muller exporters in India. With our manufactured Sand Muller, you can expect that there will be consistent mixing results batch after batch. This consistency that you get with our made sand muller is super essential for ensuring the quality and integrity of the construction materials being produced, leading to better overall project outcomes.

Features : -

- Batch type sand mixer muller sturdy construction

- Long life even at high working time

- Two muller with wide mulling face

Mullers :- Two mullers with wide mulling face and proper weight to give efficient and maximum mulling action without crushing the sand.The mullers are in hinges and supported by springs , mullers floting over the sand at constant pressure.

Scrapers :- Two scrapers are provided and are so designed that one brings the sand under the muller and the other takes it out.

Crib :- It is fabricated from MS plates and reinforced at the top and bottom to prevent any distortion while the machine is working. The crib is bolted to the pan base and is detachable for maintenance purpose.

Specification :-

|

Type |

SMM 1000 |

SMM 1250 |

SMM 1600 |

SMM1800 |

SMM 2400 |

|

Capacity |

150kg |

250kg |

500kg |

750kg |

1000kg |

|

No. of rollover |

2 Nos. |

2 Nos. |

2 Nos. |

2 Nos. |

2 Nos. |

|

Pan Diameter |

1000mm |

1250mm |

1600mm |

1800mm |

2400mm |

|

Crib Height |

550mm |

600mm |

700mm |

800mm |

1000mm |

|

Power |

5 HP |

10 HP |

15 HP |

20 HP |

30 HP |